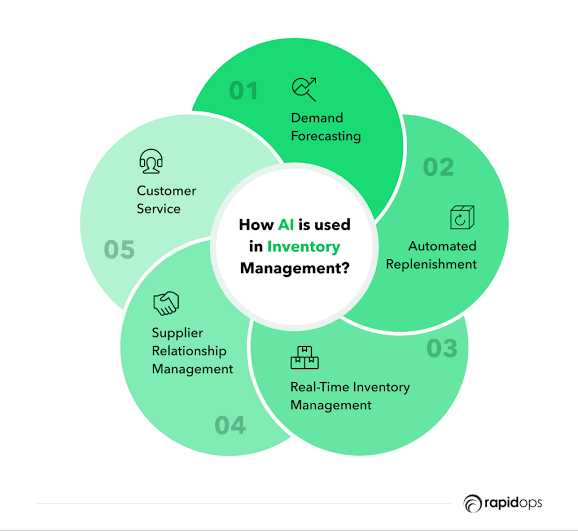

Explore how AI-driven inventory management is revolutionizing supply chain efficiency. Learn about improved forecasting accuracy, real-time tracking, automated replenishment, and cost-saving benefits. Discover how AI can optimize your inventory and enhance customer satisfaction.

The incorporation of intelligence (AI) in inventory management is reshaping the efficiency of supply chains. AI powered systems are playing a role, in streamlining inventory operations cutting costs and improving overall effectiveness. This article delves into the impact of AI on inventory management and offers guidance on utilizing this technology for enhanced performance.

Understanding AI in Inventory Management

The application of intelligence in managing inventory involves the use of learning algorithms, data analysis and automation to enhance the processes of monitoring, predicting and making decisions. Unlike conventional methods that depend on inputs and past information AI powered systems leverage data and sophisticated analytics to forecast inventory requirements with precision and adapt swiftly to fluctuations in demand.

Enhanced Forecasting Accuracy

One significant advantage of AI lies in enhancing the accuracy of forecasts. AI algorithms process amounts of information such as past sales patterns, seasonal variations, market dynamics and social media insights to generate precise demand projections. This methodology provides forecasts, than conventional techniques assisting companies in preventing both stock shortages and excess inventory.

Real-Time Inventory Tracking

AI technology provides better tracking of inventory, than traditional approaches. By utilizing Internet of Things (IoT) sensors, RFID tags and automated data collection methods companies can keep an eye on inventory quantities, locations and movements in time. This level of insight enables businesses to quickly resolve inventory issues, optimize stock management and minimize the chances of lost sales or overstocking.

Automated Replenishment

AI shines in automated restocking. By assessing data and inventory status AI can initiate reorder processes when stock drops below preset limits. This automation decreases human involvement, minimizes mistakes and guarantees prompt restocking. It helps keep stock levels and lowers the chances of running out of items.

Optimizing Supply Chain Operations

AI boosts supply chain effectiveness by examining and improving areas like supplier performance, delivery times and transportation paths. It spots inefficiencies and recommends enhancements enabling companies to streamline their supply chain processes reduce expenses and enhance delivery speed. For instance AI can enhance warehouse configurations propose shipping routes and foresee possible disruptions helping businesses tackle problems, in advance.

Demand Sensing and Adaptive Supply Chain

Demand sensing plays a role, in leveraging AI technology to help companies adjust to evolving consumer preferences and market dynamics. By analyzing data from sources such as sales records, online feedback and social media AI systems can identify changes in demand trends. Integrating this information into inventory management enables businesses to modify stock levels and supply chain approaches ensuring they stay competitive and responsive to shifting market conditions.

Reducing Operational Costs

AI powered inventory management leads to savings in ways. Enhanced prediction capabilities decrease the risk of running out of stock or having excess inventory reducing storage costs and urgent restocking situations. Automation streamlines manual inventory monitoring and order handling leading to labor cost savings. Furthermore AI assists companies in spotting opportunities for bulk purchases and negotiating improved terms with suppliers, boosting overall cost effectiveness.

Enhancing Customer Satisfaction

Managing inventory is crucial, for keeping customers happy. AI technology helps make sure products are in stock when needed reducing situations where items are out of stock or delayed. By tracking things and predicting demand accurately orders can be processed quickly leading to better customer satisfaction and loyalty. Adjusting inventory levels and streamlining the supply chain ensures that products are delivered. On time and reliably meeting what customers want.

Challenges and Considerations

While AI powered inventory management offers advantages it also comes with obstacles. Deploying AI technology demands a financial commitment in terms of both infrastructure and the know how to analyze data and utilize machine learning. Companies must integrate AI solutions into their workflows while safeguarding data privacy and security in accordance, with applicable regulations.

Conclusion

The utilization of AI in managing inventory is revolutionizing the effectiveness of supply chains. Through the use of analytics, up to data and automation AI technology improves the precision of predictions simplifies the monitoring of stock and enhances the functioning of supply chains. The advantages encompass accuracy, cost savings, customer satisfaction and heightened operational effectiveness. With progress companies that embrace AI powered inventory management will have an edge, in handling supply chains and attaining success in the run.